At Burnsall Engineering we understand the difficulties involved in the transition from component visualisation to a finished moulded rubber part, & endeavour to support our customers every step of the way.

Quoting

From first contact, our quoting & technical team can offer guidance on the best way to mould rubber parts, & therefore an appropriate design solution, drawing on nearly six decades of mould making experience.

Prototyping

We also offer our services for prototyping which provides accurate feedback on moulding & de-moulding conditions when faced with complicated rubber components. Many of our partners find this initial R&D invaluable when unsure of the rubber compound's properties, how the part will work in application or about how to efficiently remove the part from the mould when dealing with complicated 3D forms. We recommend prototyping prior to a suite of large mould tooling as a safeguard against costly modifications in the future.

Design

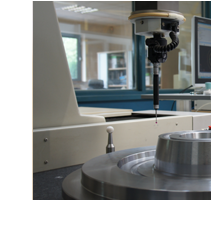

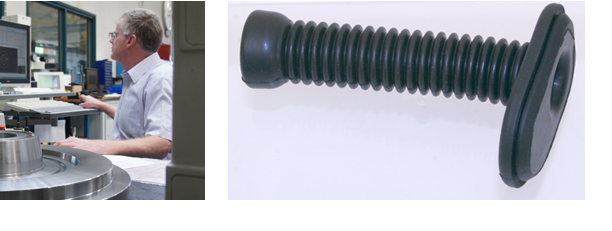

Our in-house design team liaise with customers to create the mould tool they envisage, with all manufactured details being individually created & drawn in state-of-the-art 3D modelling software. There is also the service of reverse engineering parts to create component models & drawings (for use with a mould order only), helping those with less information than they would have liked from their customer. In some cases we create component models from scratch, purely from our customer's imagination & requirements!

Trialing

Most rubber moulds shipped from our plant are cold moulded with a shrink free rubber prior to dispatch to confirm cavity sizes. Whilst this is only available on small to medium compression tools, we occasionally arrange trials outside with reputable moulders if the customer cannot trial it themslves.

Actual, on-site mould trialing is only offered on small/medium compression tools that are to be exported. Cavity sizes on larger tools are inspected to guarantee conformity.

A member of our Technical Team can be on your site during the first trials to help fine tune the moulding process.

Support

Our commitment to quality tooling means that if things are not quite how they should be when moulded, we will pick up & rectify the tool as a priority. Some more complicated rubber mould tools may require 'tweaking' after trialing with regards to the flow of rubber & air through the tool, & whilst our experience helps eliminate the majority of traps at the design stage, we stand by our customers, providing a quick turn around in these scenarios to get you up & running again as soon as possible.

|